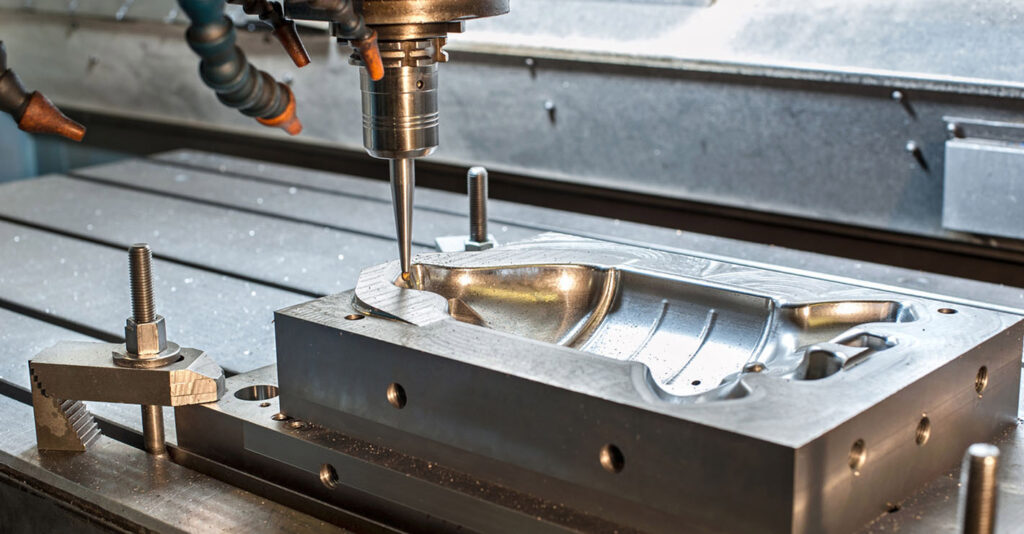

RAPID TOOLING

Rapid Tooling is when Rapid Prototyping techniques and conventional tooling practices are used together to produce a mold quickly. This process is also used to prepare parts of a model from CAD data in less time and at a lower cost compared to traditional manufacturing methods. Rapid Tooling is used as a channel to produce injection molded parts. Injection moulding is used for rapid prototyping and for low-high volume manufacturing. It is used for producing parts in the thousands. Well known examples of injection moulding are lego bricks, bottle caps, and medical syringes.

PRODUCT DETAIL

- We provide high production tooling for in house molding or for export.

- Single Cavity, multicavity, family molds,2 shot, Hot Runner Valve gate,

- Tooling materials for production molds are typically P20, H13, S7, NAK80.

- Customers can select materials types when quoting

- All export molds are sampled and run for several hours to ensure good operation prior to shipping..